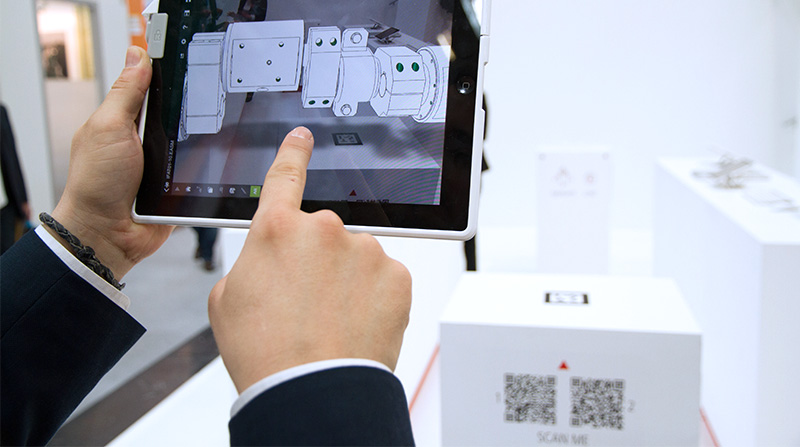

Bianna MassMak is launching an after-sales service focused on equipment and plants spare parts through augmented reality which will be presented at the IFAT 2018.

This new system is used to identify which part needs to be replaced o mended in a treatment plant. The objective is threefold: to identify virtually all the equipment parts, to have remote access to all documentation related to the machine and finally to process the order of the required spare parts. In conclusion, the less time it takes, the fewer mistakes are made.

How does it work?

The QD code makes available a whole set of documents related to the machine which has been acquired by the client (operating manual, warranty, parts…). At the same time, it also allows watching the equipment in 3D when interfacing with it, having access to its components and identifying each of them with the code of the part, operating manual, current instructions, etc.

An ordinary Smartphone can be used to access the code, so the part which must be replaced or mended can be identified. As a result, failures are reduced.

- FAILURE REDUCTION: Quick and intuitive identification of the part which needs to be replaced or mended.

- QUICKNESS: Rigorous spare parts procedure with no need to move for the Technical Assistance Service.