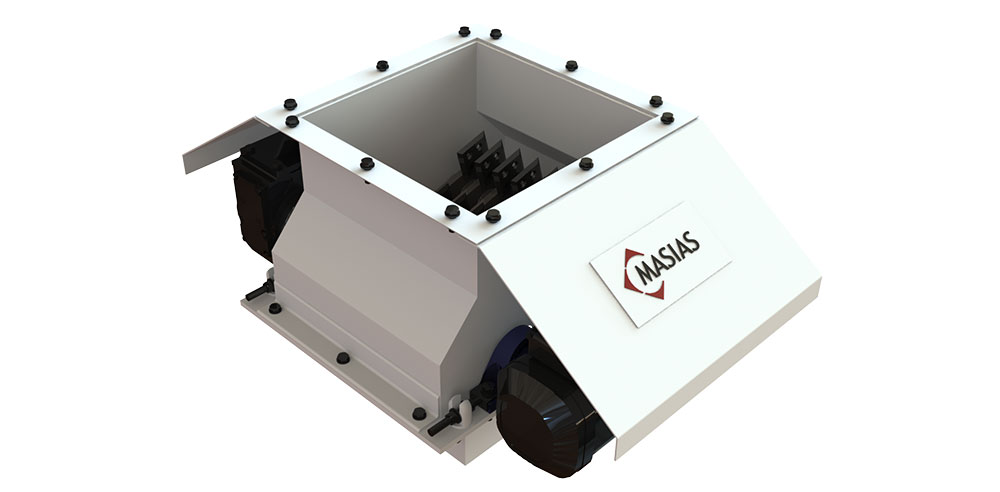

BOTTLE PIERCER

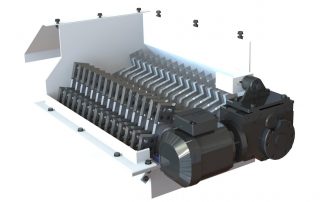

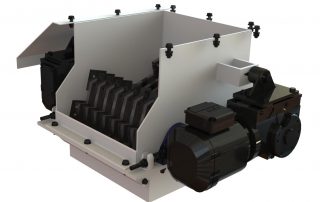

Bianna MassMak’s bottle piercer is a very effective equipment, the aim of which is to drill light packaging, mostly PET packaging to increase the efficiency of the pressing bales, improving density and stability of these bales and the performance of the equipment thanks to a better compaction.

Easy installation and handling compact equipment, specifically designed to be adapted to different input material.

ADVANTATGES

- Great drilling efficiency in light packaging.

- Easy installation and maintenance compact equipment.

- Good production-invest cost ratio.

- Top brands standard components.

- Adjustable axes distance to be adapted to the input flow.

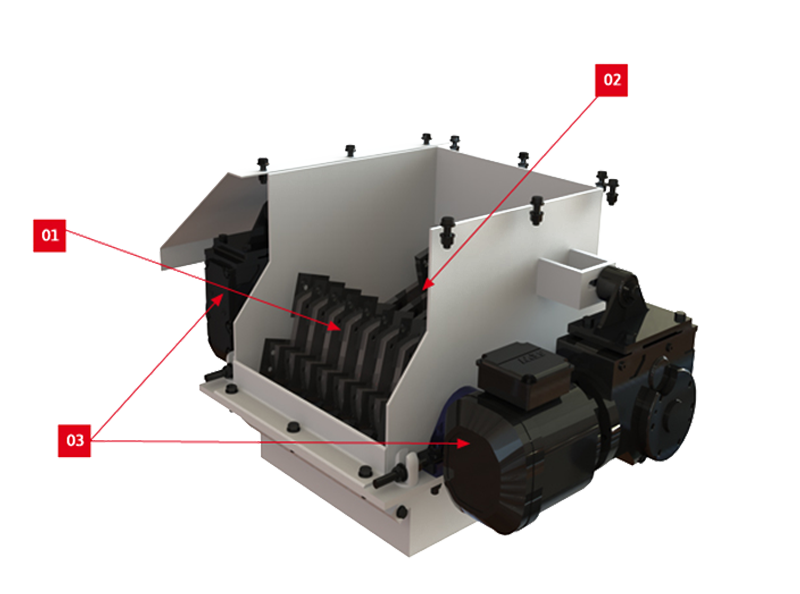

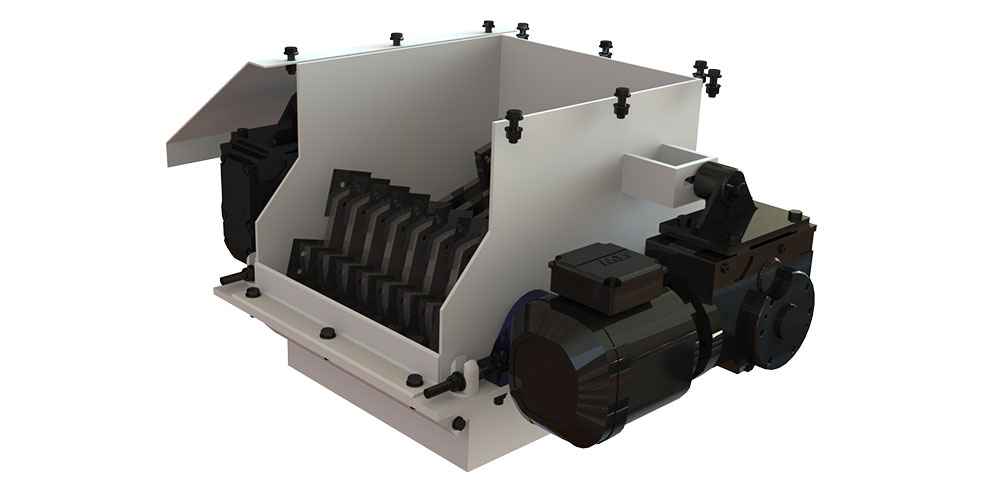

MAIN PARTS

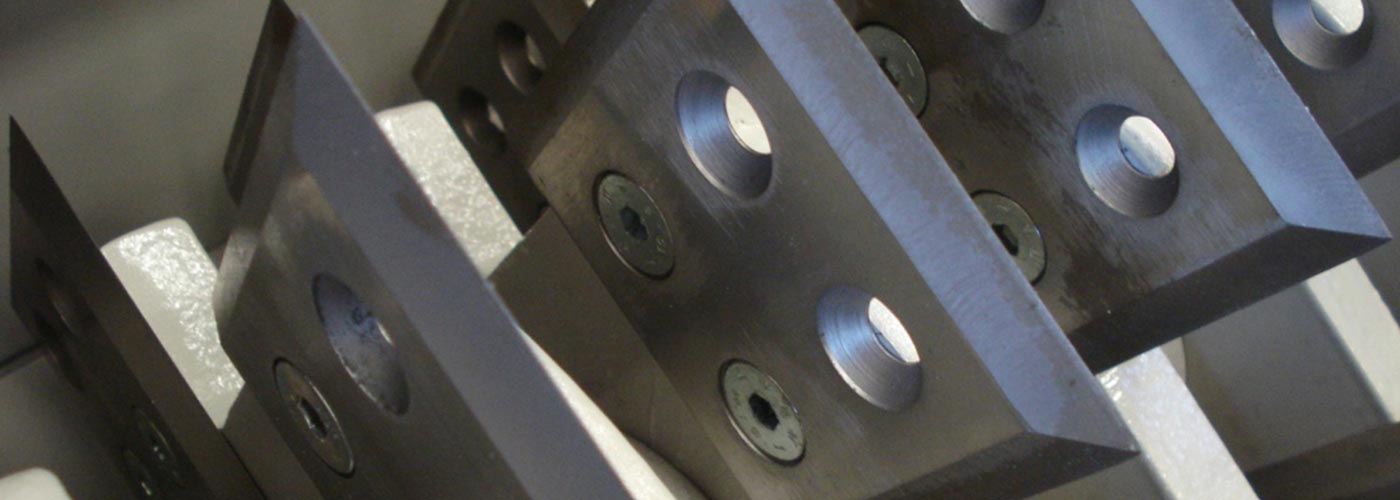

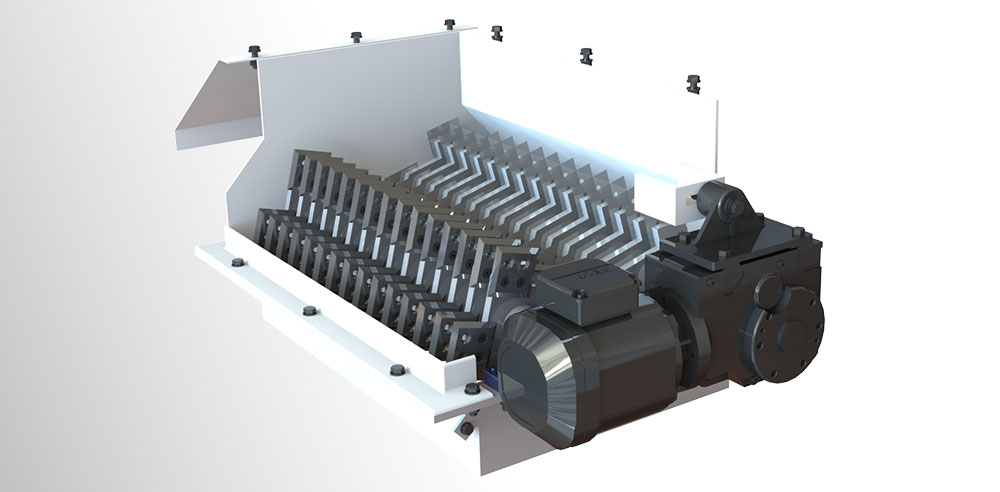

01 • Blades: Every holder has got four blades which, besides being interchangeable are reversible on all four sides, optimize their durability. The bottle piercer includes a spike set in order to make a good cleaning amid blades suppors.

02 • Blades holder: Blades holder is fit with the axes and number of blades and holders will depend on the equipment model.

03 • Gear motors: There are two gear motors, one for each axe. A fixed motor and a motor which can be driven in order to adjust the distance amid axes of 270 and 300mm by a tuner.