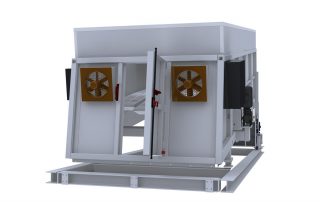

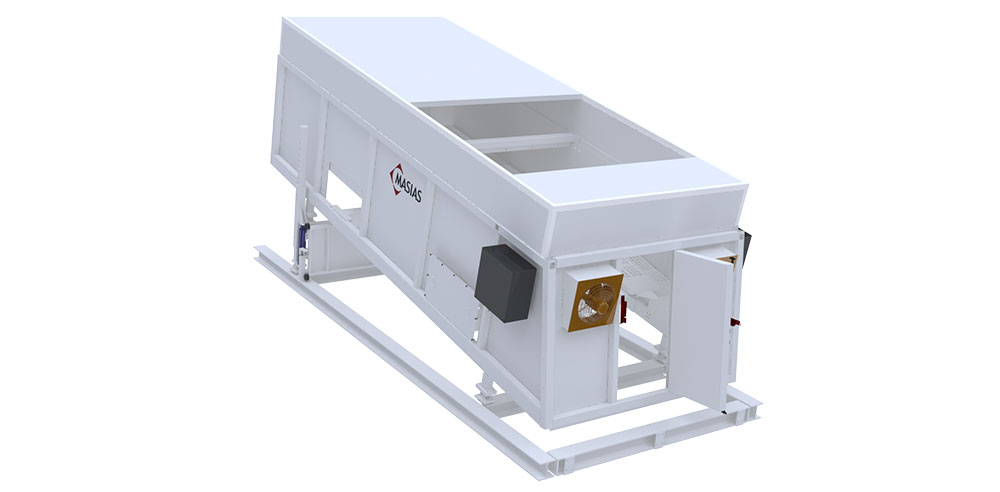

BALLISTIC SEPARATOR

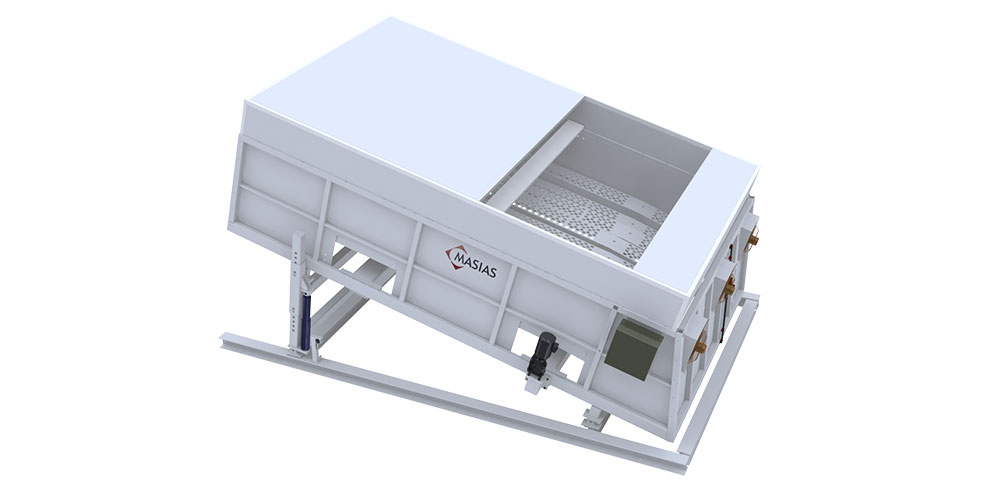

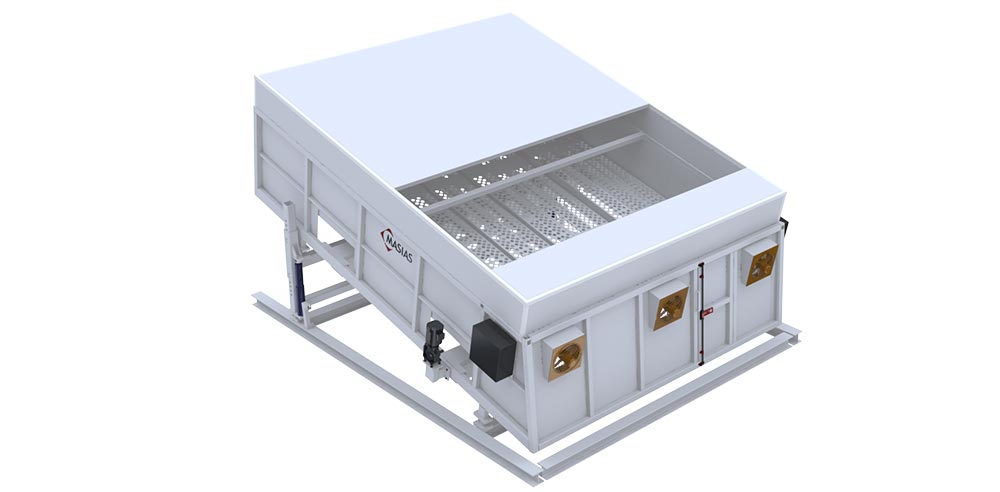

Widely known for their reliability and efficiency, Bianna MassMak’s wide range of ballistic separators are used in RSU, EELL and CSR plants. There is the possibility to adjust different parameters in order to adapt automatically the type of material, from the fan speed to the equipment slope.

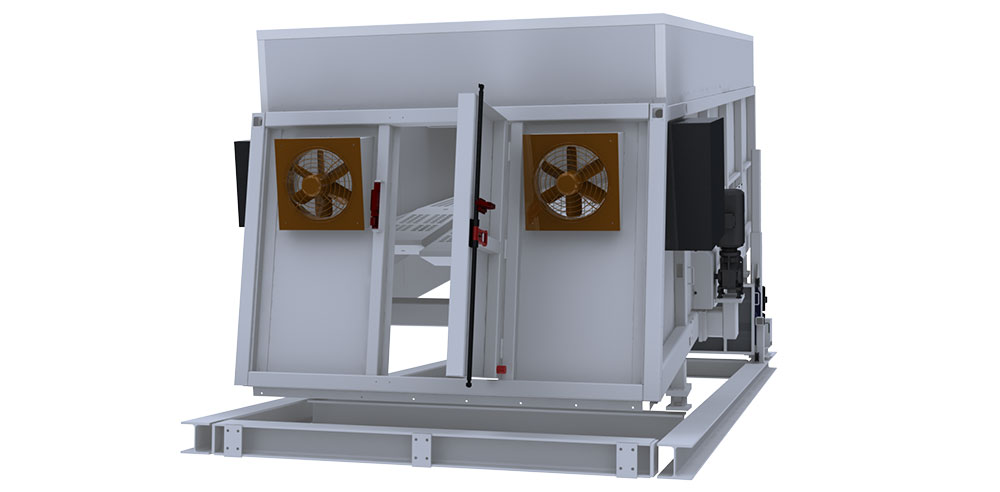

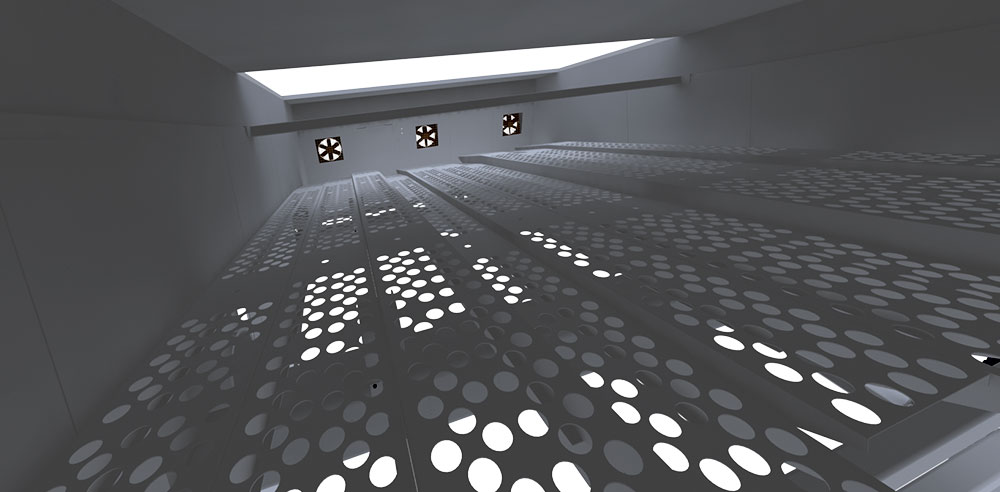

The equipment is especially designed to make cleaning and maintenance easier, and it is supplied with different devices which make the inside of the ballistic as ergonomic and comfortable as possible.

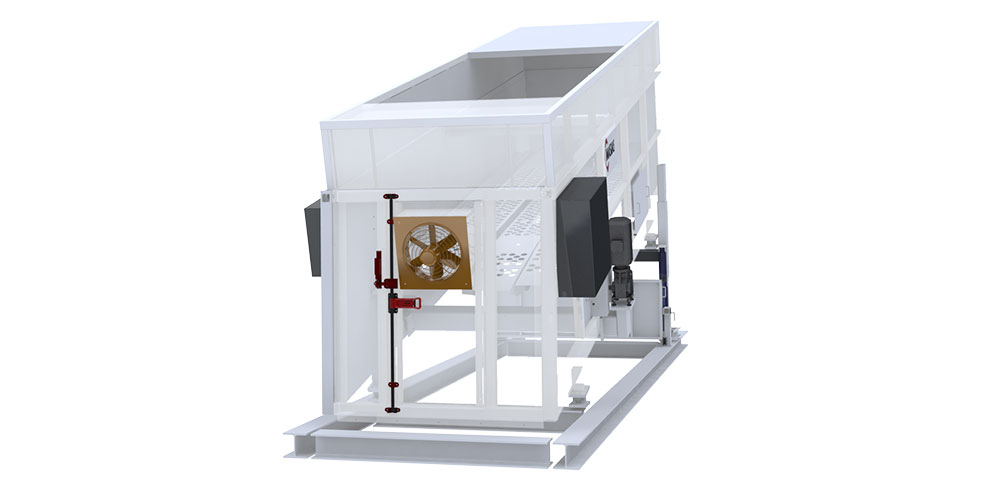

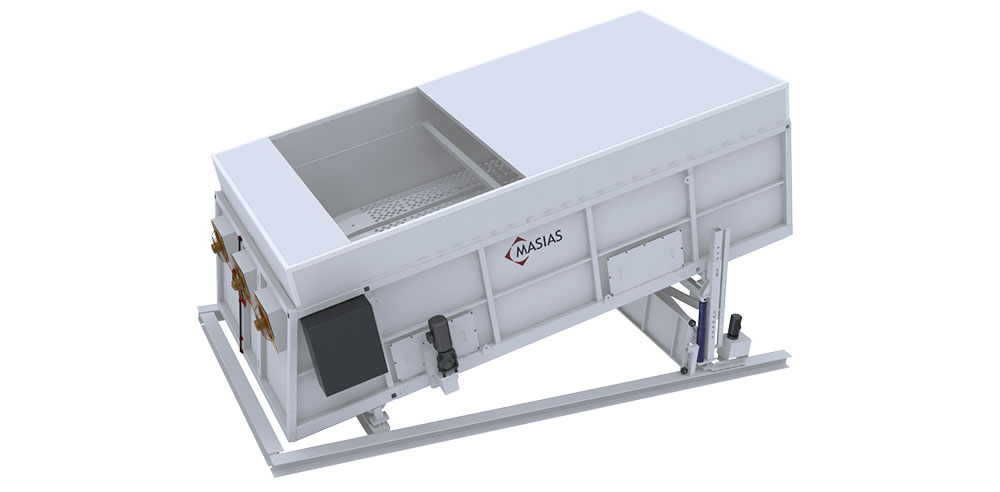

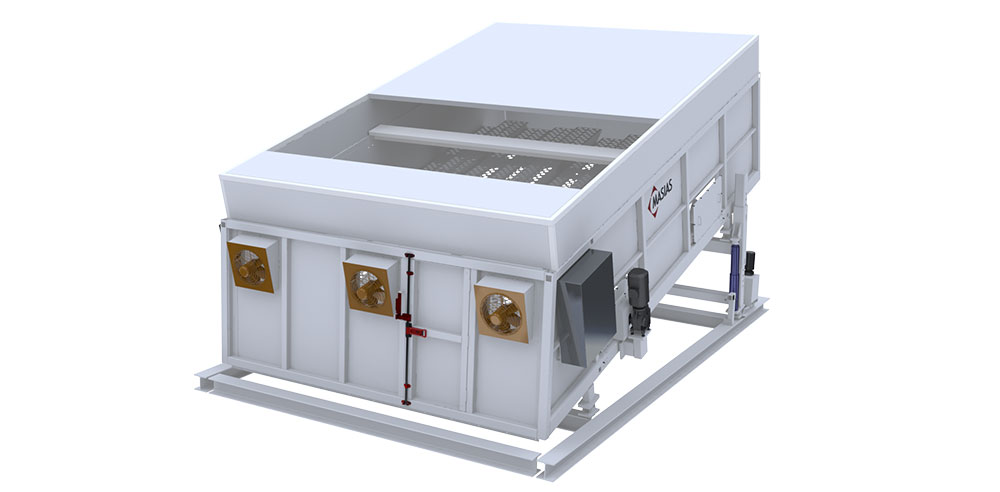

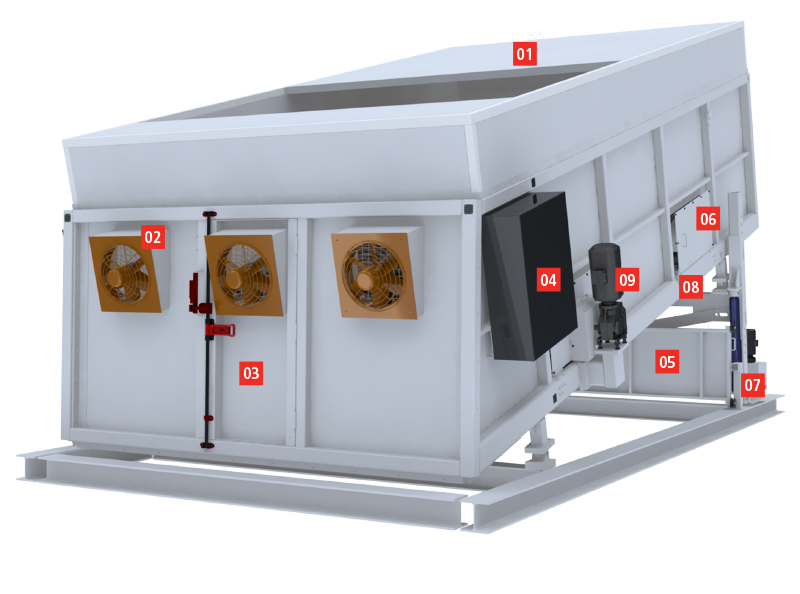

MAIN PARTS

01 • Raised roof

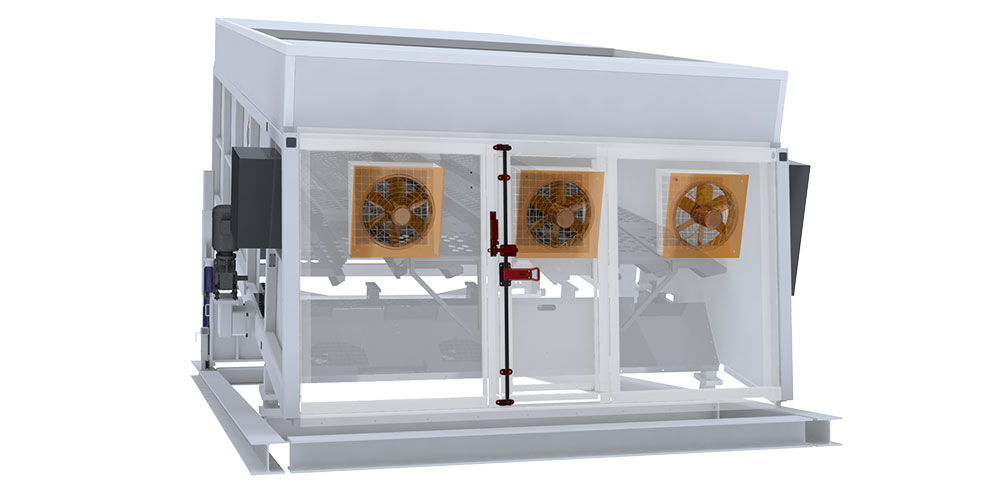

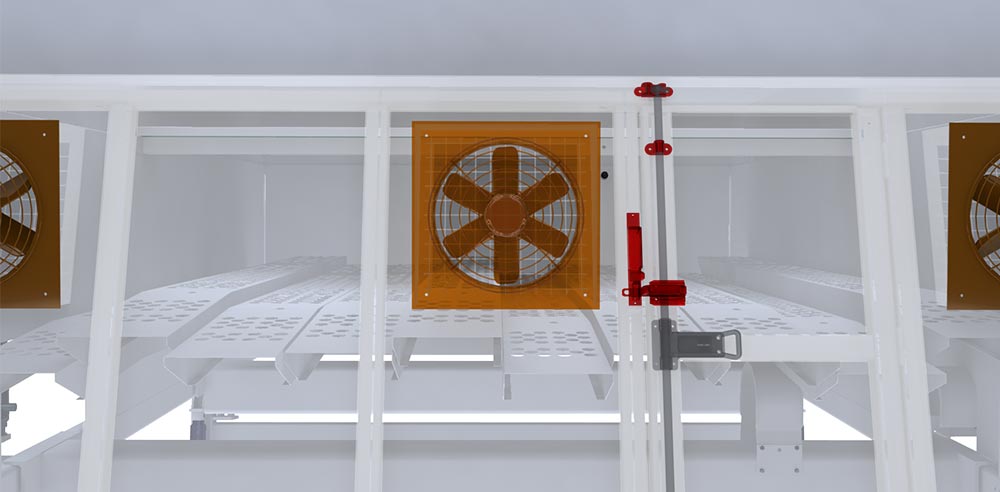

02 • Impulsion fan

03 • Door and access ramp

04 • Electric pannel

05 • Maintenance cart

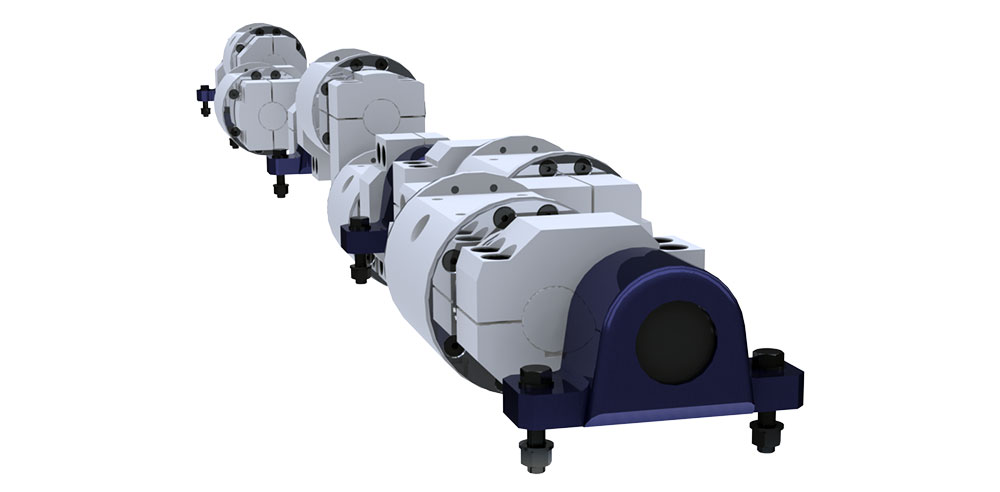

06 • Crankshaft maintenance access.

07 • Hydraulic lifting system.

08 •Centralised lubrication system

09 • Gearmotor with brake

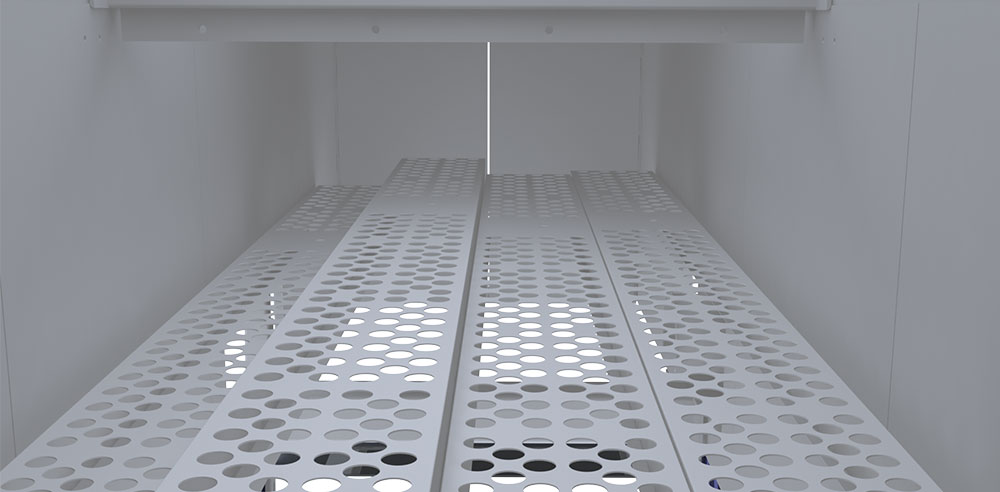

The equipment includes a ramp with longitudinales perforate plates which make a ballistic type of movement generated by two crankshaft placed below them. The equipment slope and the plates rotary movement allows the input flow to be separated in three different fractions.

3D: Rolling fraction, bottles, cans, light packaging, etc.

Fine fraction: sand, remaining of organic fraction, etc.

2D: Flat fraction, paper, cardboard, etc.