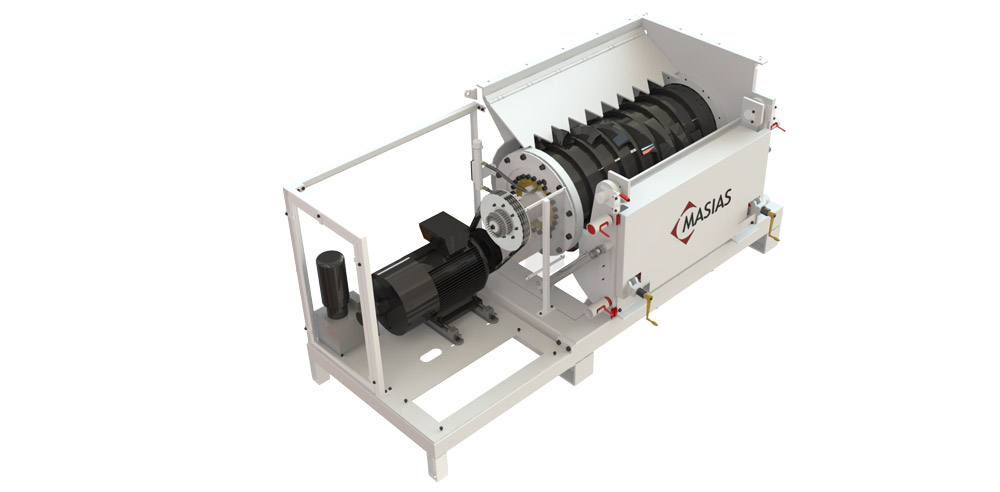

OPEN CRASH

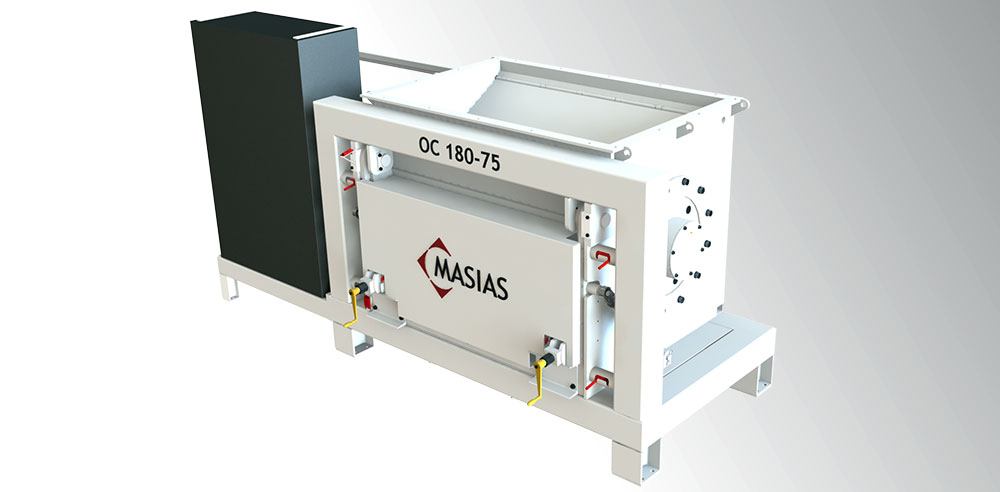

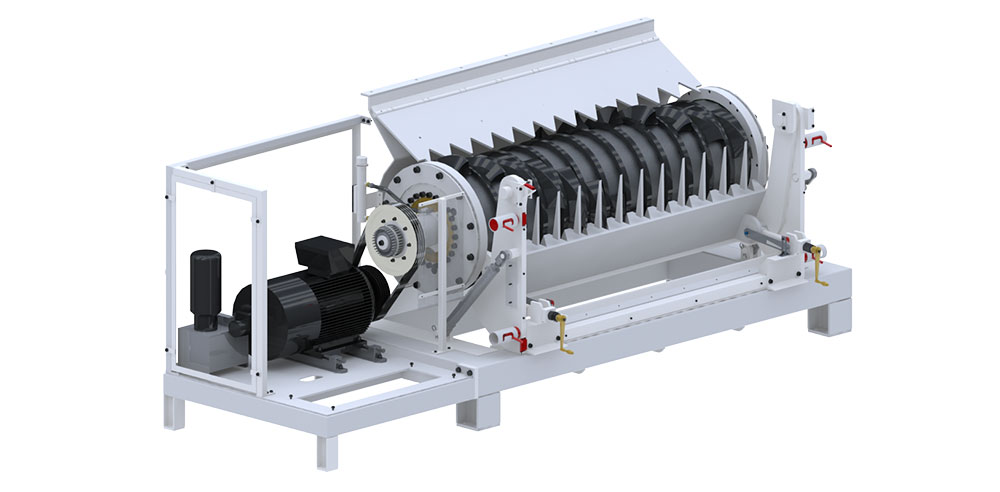

With the goal of assuring an efficient bag opener getting to urban and packaging waste treatment plants, Bianna MassMak has developed a great bag opener equipment which is characterized by its maximum efficiency and low operating costs.

Bag opener great performance (efficiency superior to 95%) avoiding aggressiveness with the inside material of the bags and increasing any selection process efficiency as well as the recovery of recyclable materials.

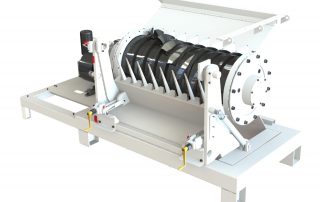

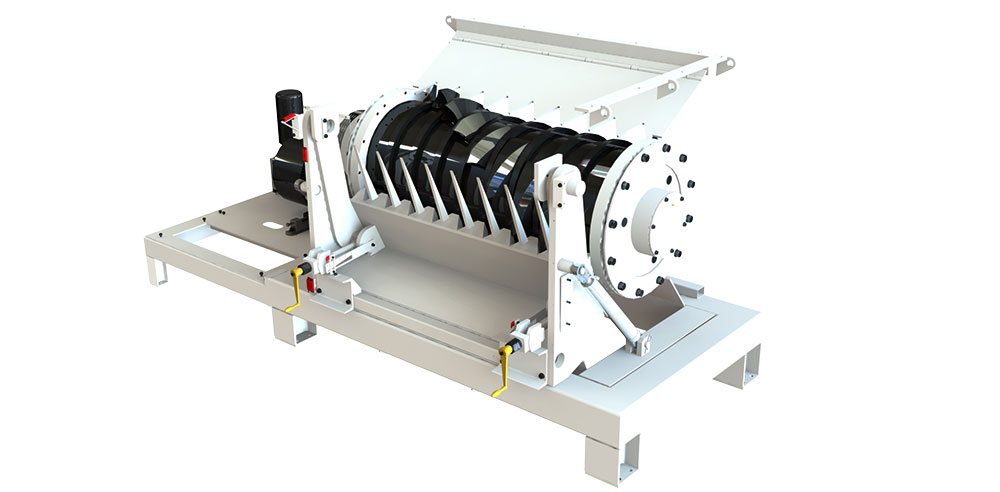

The equipment rotor runs at low Rpm driven by an electric motor. The motor transmission system to the rotor includes a belt and a planetary gearbox. The rotor speed can be controlled by a frequency shifter (from 0 to 12 Rpm).

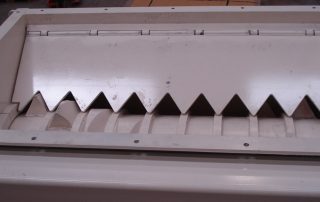

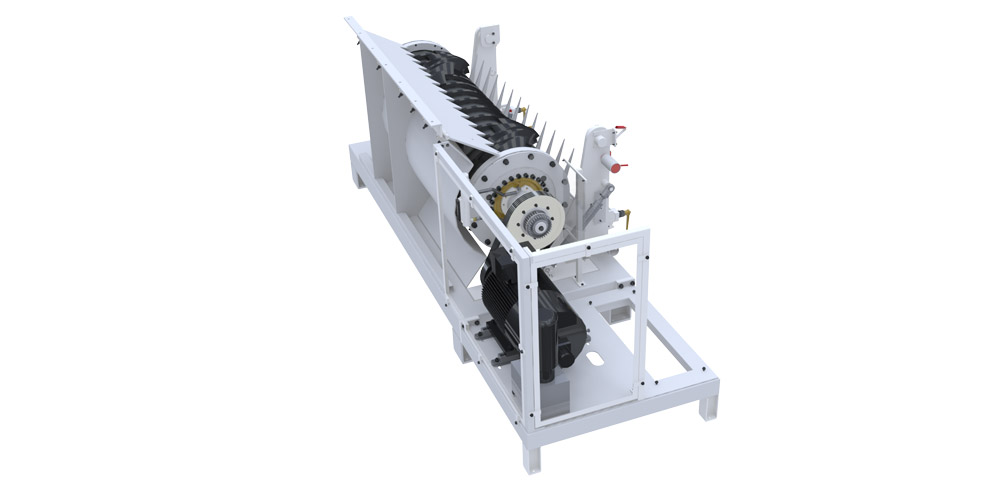

The rotor incorporates a number of sharp teeth placed in a spiral pattern throughout its surface, opening the bags while being ripped by fixed teeth. The distance between the teeth of the rotor and the static rippers is adjustable from 5 mm. to 150mm.

The rotor teeth and the static rippers distance is adjustable from 5 mm. to 150mm.

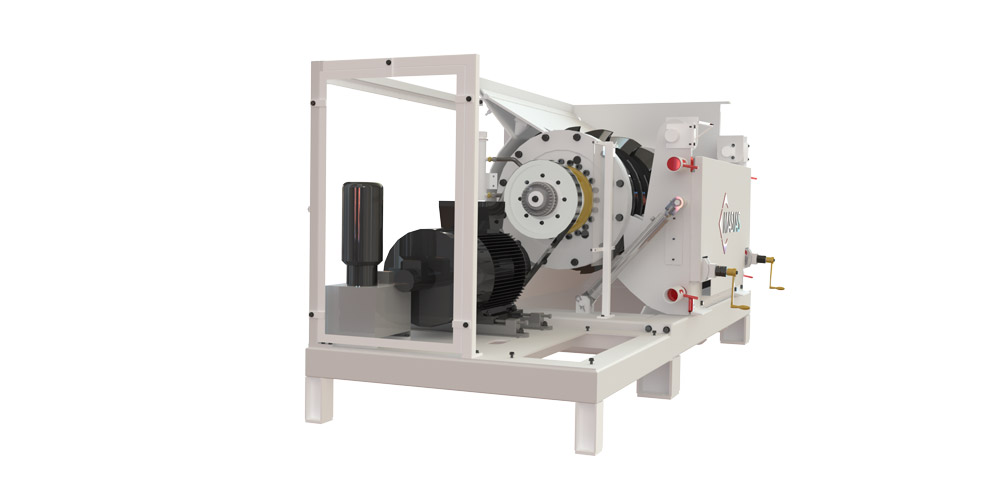

MAIN PARTS

1 • Rotor

2 • Mechanical regulation distance between the rotor and the counter-cutter.

3 • Equipment side gate with an hydraulic lifting system to carry maintenance tasks and getting rid of unwanted materials.

4 • Planetary gearbox.

5 • Electric motor.

6 • Rotor cleaning plate.

7 • Electrical panel

MAIN FEATURES

- Slow rotor with adjustable speed.

- Planetary gearbox for the movement transmission from the electric motor to the rotor shaft.

- Control system to assure the equipment performance facing complex materials: rotor inversion or automatic stop of the equipment.

- Distance adjustment between the rotor and the counter-blades holder.

- Control cabinet fitted with PLC Siemens S7.