TROMMELS

Screening trommels are an essential part of waste pre-treatment facilities, since most part of mechanical pre-treatments to which waste is subjected depends on his separation efficiency.

Trommels are used in a wide spectrum of applications in order to separate the organic material in urban and packaging treatment plants, not only to eliminate the voluminous material but also to separate inert material in compost refine plants.

Bianna MassMak offers a wide range of trommels with different diameters, screening lengths and plate thickness, depending on the equipment application: simple / double trommels for urban treatment plants, refine trommels, trommels for construction and demolition waste treatment facilities, etc.

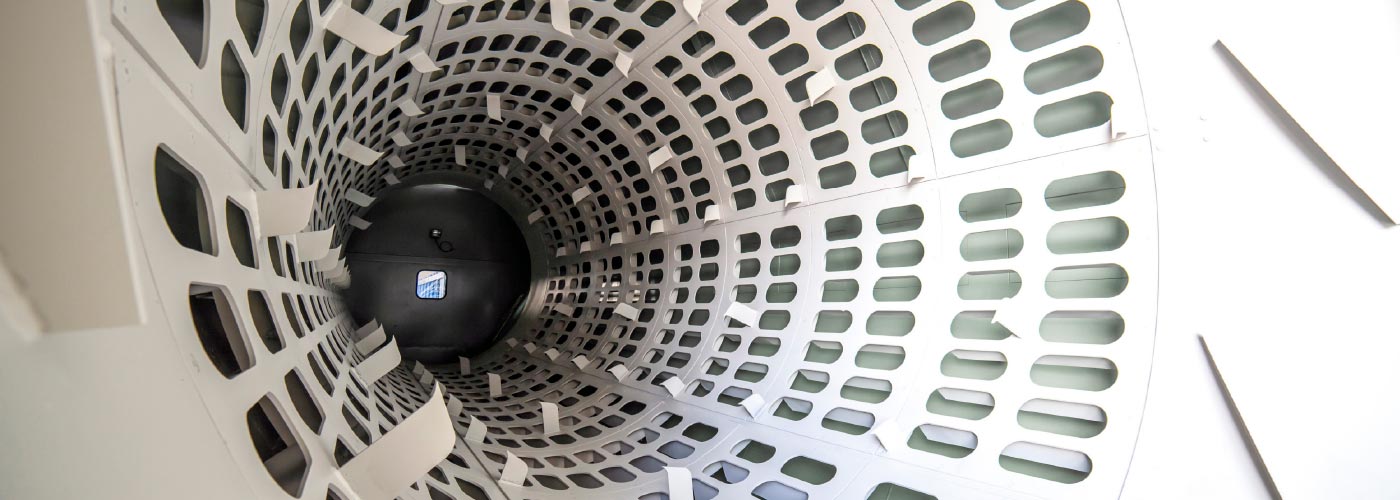

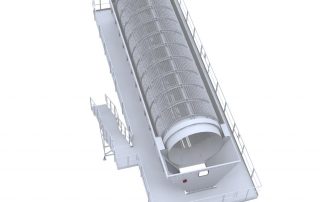

MAIN PARTS

01 • Protections an sheet upper covering

02 • Screening drum: sheet thickness (from 6 to 15 mm). Mesh size according to the screening request.

03 • Wearing resistance wheels

04 • Guide wheel

05 • Gearmotor

06 • Drum

07 • Support strut

08 • Access door to the inside of the equipment

09 • Inspection window

10 • Maintenance platforms

11 • Access stairway

12 • Anti-strip system (optional)

13 • Bag-opening teeth

14 • Exchangeable screening sheets.

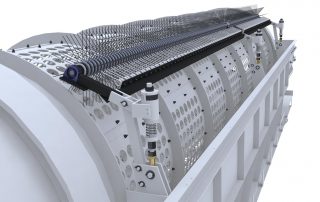

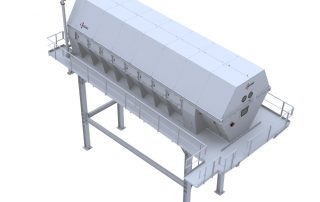

STATIONARY

TROMMEL

Screening trommels are an essential part of waste pre-treatment facilities, with different screening diameters and lengths for RSU, packaging, CSR and bulky waste treatment.

Our trommels, sold worldwide for more than 25 years, guarantee our equipment efficiency and durability. They are distinguished by the fact they have security systems installed and all the access to the inside of the trommel are specifically designed to guarantee the cleaning and maintenance work to be as practical and fast as possible.

ADVANTAGES:

- Great efficiency separation.

- Robustness and durability thanks to a careful design.

- Low maintenance cost.

- Exchangeable meshes ( 10 mm sheet thickness).

- Low energy consumption.

- Possibility of incorporating the open bag system which is specially designed for this equipment.

- Anti-straps system to avoid excessive cleaning works.

| MODEL |

Diameter (mm.) |

Tamiz length (mm.) |

Total length (mm.) |

Power (kW) |

Performance (m3/h) |

|---|---|---|---|---|---|

| TR2,1/5/7 | 2.100 | 5.000 | 7.000 | 11.0 | 55 |

| TR2,1/7/9 | 2.100 | 7.000 | 9.000 | 15.0 | 85 |

| TR2,5/6/8 | 2.500 | 6.000 | 8.000 | 15.0 | 70 |

| TR2,5/8/10 | 2.500 | 8.000 | 10.000 | 15.0 | 110 |

| TR2,5/10/12 | 2.500 | 10.000 | 12.000 | 2 x 11 | 130 |

| TR2,5/12/14 | 2.500 | 12.000 | 14.000 | 2 x 15 | 155 |

| TR3/8/10 | 3.000 | 8.000 | 10.000 | 15 | 150 |

| TR3/10/12 | 3.000 | 10.000 | 12.000 | 2 x 11 | 175 |

| TR3/12/14 | 3.000 | 12.000 | 14.000 | 2 x 15 | 210 |

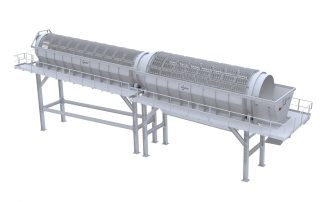

C&D

TROMMELS

Equipment characterized by its robustness and wear resistance in demolition plants. Working with such waste is no easy task, so Bianna MassMak has designed very rugged equipments which are able to withstand the wear and abrasion this kind of waste involve.

ADVANTAGES:

- Great separation efficiency.

- Longer lifespan thanks to a careful design exclusively for RCD’s.

- Possibility of replacing the trommel’s mesh with no need to change the equipment (15mm thickness plate).

- Opcionalmente, el tambor se recubre con goma para disminuir los desgaste y los niveles sonoros

- Optionally, the drum can be covered with rubber in order to reduce wear and noise levels.

- Low maintenance and cleaning costs.

| MODEL |

Diameter (mm.) |

Tamiz length (mm.) |

Total length (mm.) |

Power (kW) |

Performance (m3/h) |

|---|---|---|---|---|---|

| TR2,1/5/7 D | 2.100 | 5.000 | 7.000 | 15.0 | 55 |

| TR2,1/7/9 D | 2.100 | 7.000 | 9.000 | 15.0 | 70 |

| TR2,5/6/8 D | 2.500 | 6.000 | 8.000 | 15.0 | 85 |

| TR2,5/8/10 D | 2.500 | 8.000 | 10.000 | 18.5 | 110 |

| TR3/8/10 D | 3.000 | 8.000 | 10.000 | 18.5 | 145 |

| TR3/10/12 D | 3.000 | 10.000 | 12.000 | 2 x 15 | 175 |

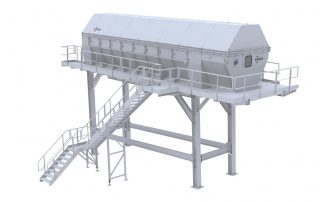

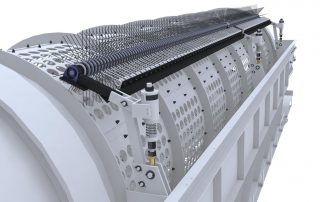

REFINE

TROMMEL

The refine trommel is the first step to separate compost from organic material and impurities, getting a high quality product. That’s why is an essential equipment in the refine compost facilities.

ADVANTAGES

- High quality compost results thanks to a careful design.

- Great separation efficiency.

- Possibility of replacing the trommel mesh with no need to change the equipment (6 mm thickness plate).

- Automatic drum cleaning by brushing.

- Reduced equipment wear.

- Optional conveyor belt.

- Low energy consumption.