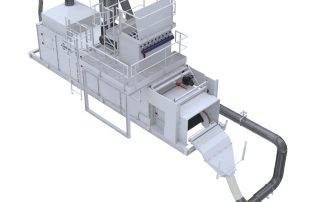

WINDSIFTER

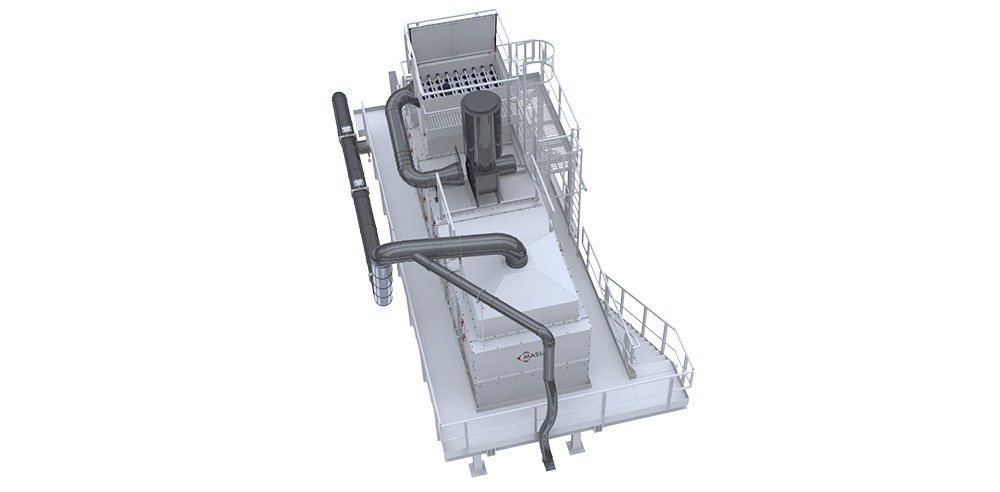

The Windsifter is a rugged equipment with great capacity to separate the light material from the heavy one. The aim of which is the separation of the inert material (stones, scrap, stainless steel) so availability and durability of the secondary shredders of alternative fuels production lines can be increased, thereby assuring a low operating cost.

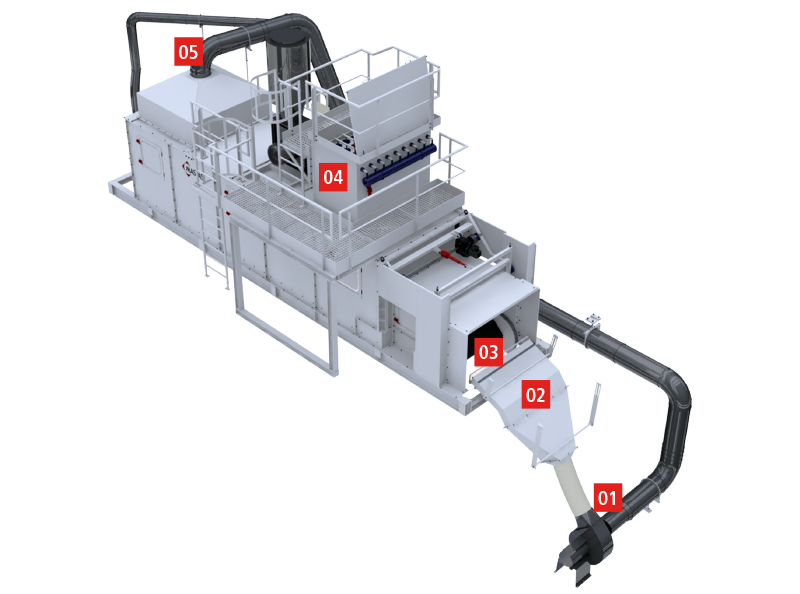

MAIN PARTS

01 • Impulsion centrifugal fan, adjustable by the frequency shafter from the touch-screen of the equipment

02 • Impulsion air nozzle adjustable in height and slope with checking windows

03 • Conveyour belt “banana type”: it allows to be adjusted in height, slope and speed depending on the material to be treated

04 • Sleeve filter with automatic cleaning system by compressed air and vibration

05 • Reduction of odours and dust emissions using a closed air system

FEATURES

To adjust the separation efficiency and depending on the material to be treated, the equipment allows the speed of the output material, the position, the slope and the airblow system power of the conveyor belt to be fixed.

The airblow system helps improving the separation of the light and heavy materials efficiency through the air impulsion. It has got a suction system with a dust filter and air recirculation which prevents dusting emissions from getting into the atmosphere.

To guarantee the staff security and improve the maintenance tasks, the equipment is provided with accesses to ease the cleaning.